Introduction

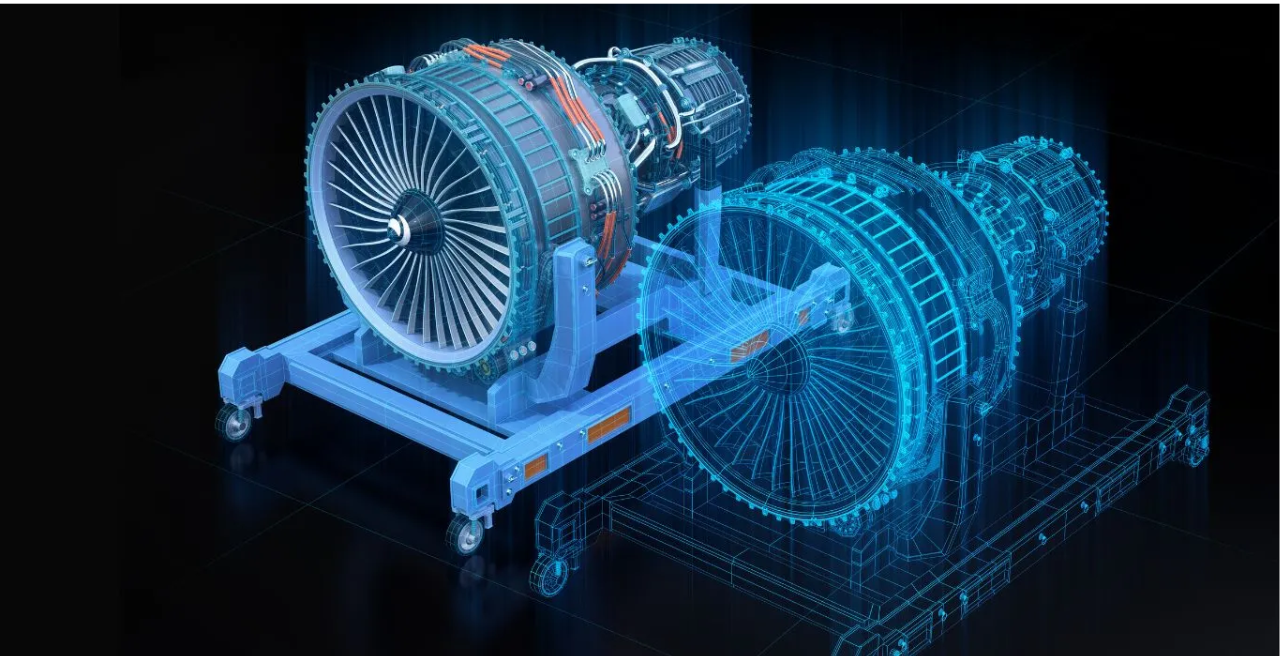

The digital transformation of engineering is revolutionizing how products are designed, tested, and deployed. One of the most groundbreaking innovations in this space is the Digital Twin. More than just a buzzword, a Digital Twin is a dynamic, real-time virtual model of a physical object, system, or process. It uses data and simulation to mirror, predict, and optimize performance—helping businesses across industries reduce costs, enhance quality, and accelerate time to market.

In this blog, we explore what a Digital Twin really is, how it works, and its seamless integration with simulation tools like MSC One, a suite from Hexagon MSC Software that enables real-world performance modeling in a virtual environment.

What Is a Digital Twin?

A Digital Twin is a virtual representation of a physical product or system throughout its lifecycle. This model is continuously updated using real-time data from sensors, IoT devices, and control systems. The concept relies on the convergence of the physical and digital worlds, where data from the physical world is transmitted to the digital world for analysis, and vice versa.

Originally coined by NASA to improve spacecraft performance, Digital Twins have since expanded into various sectors—automotive, aerospace, manufacturing, energy, healthcare, and more. The ultimate goal is to simulate, monitor, and optimize the performance of physical systems using their digital counterparts.

The Core Components of a Digital Twin

Understanding how a Digital Twin functions requires breaking down its essential components:

1. Physical Entity

This could be a machine, vehicle, infrastructure, or even a complex process in a production line. It’s the tangible asset whose behavior is replicated in the digital space.

2. Digital Replica

The virtual model represents the structure, behavior, and context of the physical entity. It includes CAD models, physics-based simulations, control logic, and performance data.

3. Data Integration

Real-time sensor data feeds into the model, allowing it to reflect the current condition of the physical entity. This includes mechanical, thermal, acoustic, fluidic, and electrical parameters.

4. Simulation and Analytics Engine

This is where tools like MSC One come into play. They simulate how the digital model performs under various conditions, helping engineers anticipate issues, test changes, and validate designs.

5. Visualization and Feedback

The user interface provides actionable insights and allows engineers to make informed decisions. Feedback loops ensure that real-time changes are reflected back into the physical system.

How Simulation Powers the Digital Twin

A Digital Twin without simulation is just a static model. Simulation adds intelligence, enabling the digital model to behave like its real-world counterpart under various physical and operational conditions.

Here’s how simulation tools like MSC One enhance the value of Digital Twins:

Realistic Physics-Based Modeling

MSC One offers simulation tools such as MSC Nastran, Adams, Marc, Cradle, Romax,Actran etc.. which simulate structural mechanics, dynamics, non-linear behavior, and acoustics. These capabilities are critical for building an accurate and reliable digital twin.

Multiphysics and Multi-Domain Integration

Digital Twins often involve complex interactions—mechanical stress, thermal effects, fluid dynamics, and vibrations. MSC One enables multiphysics simulations by linking different domains, providing a holistic understanding of how the system behaves in real-world environments.

Scenario Testing and Predictive Analysis

Using simulation, engineers can test multiple scenarios without affecting the physical system. What happens if the material is changed? What if the operating load increases by 30%? MSC One allows rapid prototyping in the virtual world, offering predictive insights and reducing the need for physical trials.

Lifecycle Simulation

Digital Twins aren’t only about the product design stage. With MSC One, simulations can be applied across the entire lifecycle—from design and testing to operation, maintenance, and decommissioning. This results in better design decisions, improved product reliability, and reduced downtime.

The MSC One Advantage in Digital Twin Development

MSC One is a flexible, token-based licensing system that provides access to a wide range of simulation tools from Hexagon MSC Software. Here’s how it empowers engineers and businesses to create high-fidelity Digital Twins:

- Unified Access: One license gives access to multiple tools like MSC Apex, Simufact, Cradle CFD, and more.

- Ease of Collaboration: Enables cross-functional teams to collaborate using a common simulation environment.

- Accelerated Innovation: Reduces design cycles by enabling quick iteration and performance testing virtually.

- Cost-Effective: Avoids the expense of multiple licenses by offering a scalable simulation platform.

As simulation-driven Digital Twins become mainstream, the demand for platforms like MSC One continues to rise. It’s not just about modeling products—it’s about optimizing performance, reducing risks, and enabling smarter decision-making.

Real-World Applications of Digital Twins with MSC One

Digital Twins powered by MSC One are now used in industries such as:

- Automotive: To optimize vehicle dynamics, crash performance, NVH (Noise, Vibration, Harshness), and fuel efficiency.

- Aerospace: For simulating aerodynamic forces, structural stress, and fatigue life in aircraft components.

- Manufacturing: To enhance predictive maintenance and minimize equipment failure in factories.

- Energy: For monitoring turbines and grid systems under varying load conditions.

- Medical Devices: Simulating biomechanical performance of implants and wearable devices.

Conclusion

The future of engineering is increasingly digital, and Digital Twins are at the heart of this transformation. When paired with powerful simulation platforms like MSC One, they unlock a new dimension of product development and system optimization.

By integrating real-time data, realistic simulations, and advanced analytics, Digital Twins help businesses understand their systems better, make informed decisions faster, and deliver higher-performing products with less risk.

At CreoTek Systems India LLP, we help organizations across industries leverage simulation and Digital Twin technologies through platforms like MSC One. Whether you’re designing the next-generation automotive system or optimizing a factory floor, our solutions empower you to innovate with confidence.