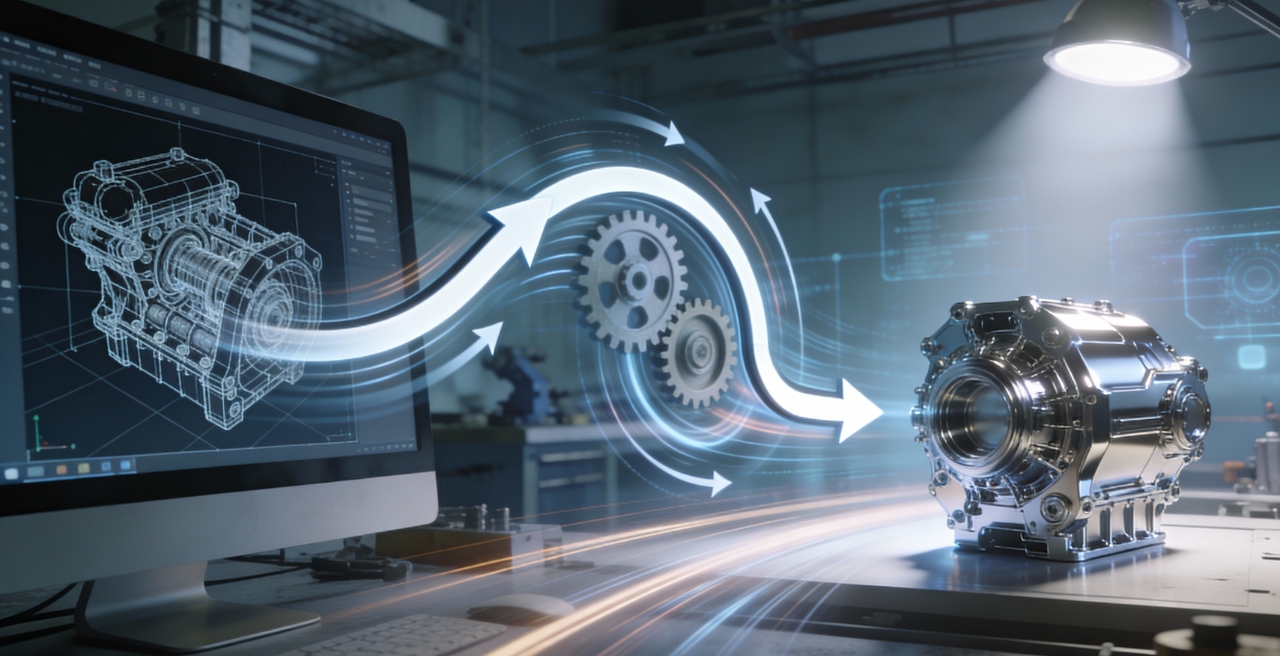

In manufacturing and engineering today, speed is essential. Companies that bring products to market quickly gain advantages in cost, innovation, and customer satisfaction. Still, many teams face slow design cycles that delay the transition from CAD models to real prototypes.

Cutting corners is different from shortening design iteration cycles. The goal is to improve workflows, choose the right tools from the start, and help teams work together more effectively during product development.

Common Causes of Slow Design Iteration Cycles

Before you try to speed things up, it helps to understand what typically slows down CAD-to-prototype workflows:

- CAD, simulation, and manufacturing systems that don’t talk to each other.

- Validation of the design is happening too late in the process.

- Not enough teamwork between the design, analysis, and production teams.

- Problems with version control and transferring files by hand.

- Many design decisions are based on physical prototypes.

These problems cause work to be done over and over, costs to go up, and product development cycles to take longer.

Strategy 1: Use Simulation Early in the Design Phase

Validating designs earlier helps reduce the number of design iterations. With simulation-driven design, engineers can test performance while changes are still easy to make.

When simulation tools are linked directly to CAD, teams can check stress, heat, airflow, and motion before building any physical prototypes.

Key benefits include:

- Early identification of design weaknesses

- Fewer physical prototypes required

- Faster, data-driven design decisions

Using simulation early in the process shortens the time from CAD to prototype and helps improve the design.

Strategy 2: Streamline CAD-to-PLM Integration

Tools that aren’t connected can cause bottlenecks that slow down iteration. A tightly integrated CAD and PLM environment makes sure that design data flows smoothly between teams.

PLM-driven design efficiency provides companies with better visibility and control over changes throughout the product lifecycle.

This approach enables:

- Centralized version and revision management

- Faster approvals and design change tracking

- Improved collaboration across distributed teams

Strong integration between CAD and PLM makes things less confusing, reduces mistakes, and speeds up the iteration process.

Strategy 3: Standardize and Reuse Proven Design Assets

It wastes a lot of engineering time to have to develop a new wheel for every project. Design reuse is a great way to speed up CAD iteration management.

Teams can spend less time on repetitive modeling and more time generating new ideas by creating standardized libraries of tested components and templates.

Effective reuse strategies include:

- Parametric templates for commonly used parts

- Reusing tested geometries and assemblies

- Leveraging past design knowledge to avoid repeated failures

Standardization makes things more consistent and reduces unnecessary design loops.

Strategy 4: Improve Cross-Functional Collaboration Early

When manufacturing or quality teams get involved too late, there are significant delays. Working together early on helps find problems before they require expensive redesigns.

Adding input from different departments during the design phase helps speed up CAD design optimization and make the switch to production easier.

This collaboration enables:

- Get early feedback on design for manufacturability (DFM).

- Check costs and feasibility more quickly.

- Reduce the number of engineering change requests (ECRs).

If teams collaborate from the beginning, design cycles tend to be shorter.

Strategy 5: Leverage Digital Prototyping and Visualization

Digital prototyping reduces the need to build in the real world and speeds up getting everyone on the same page. Before anything is made, high-quality visualization tools help teams check the form, fit, and function.

Digital prototypes support:

- Faster internal and customer approvals

- Early detection of design and usability issues

- Reduced the need for multiple physical mockups

This method speeds up the transition from CAD to prototype while maintaining the design’s correctness.

Conclusion: Faster Iterations Lead to Better Products

To stay competitive in today’s product development, companies need to reduce the number of design iteration cycles.

Teams can achieve faster CAD-to-prototype timelines without sacrificing quality by leveraging early simulation, integrated CAD-to-manufacturing workflows, standardized design assets, and strong teamwork.

In the end, making engineering design more efficient lets businesses generate new ideas faster, cut costs, and confidently bring better products to market.