Introduction

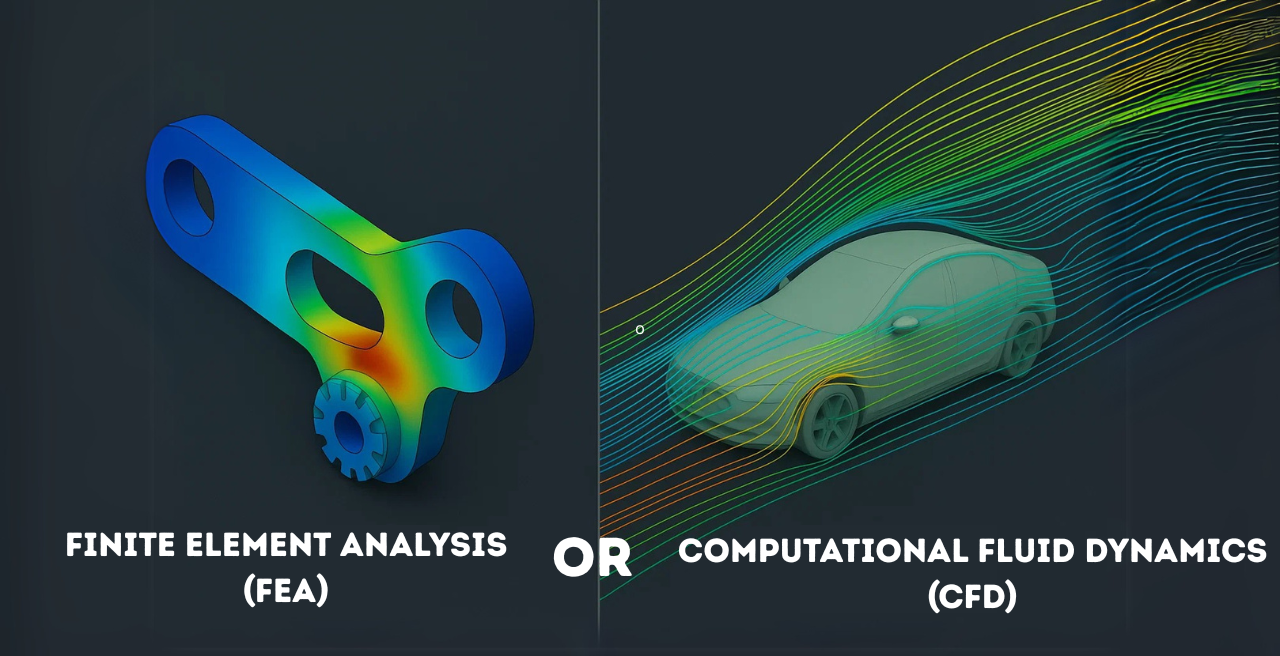

Engineers today face more pressure than ever to design better products in less time. To do that, they need the right tools. Two popular methods used to test designs before they are built are FEA (Finite Element Analysis) and CFD (Computational Fluid Dynamics). Both are powerful, but they are used for different things.

If you’ve ever wondered, “Which one should I use—FEA or CFD?”, you’re not alone. Picking the wrong tool can waste time and give poor results. But the good news is, Hexagon—a global leader in engineering software—offers both, and can help you choose the one that fits your needs.

This blog explains what FEA and CFD are, when to use them, and how Hexagon tools make the decision easier.

What is FEA (Finite Element Analysis)?

FEA is a computer-based method that helps you see how a product will react to forces, stress, heat, vibration, and more. It breaks your model into tiny parts (called elements) and solves equations on them. This helps engineers understand how the product will behave in the real world.

For example:

- Will this metal part bend under pressure?

- Will it break if the temperature gets too high?

- Will this bracket hold its shape under heavy weight?

FEA is often used in:

- Automotive components

- Structural frames

- Machine parts

- Consumer products

Main Benefits of FEA:

- Reduces the need for physical prototypes

- Finds weak points in the design

- Saves time and cost in the development process

What is CFD (Computational Fluid Dynamics)?

CFD is also a simulation tool, but it focuses on fluids and gases. It shows how air, water, oil, or any other fluid will move through or around your product. Engineers use it to understand flow, pressure, and temperature behavior.

For example:

- How does air move around a car to reduce drag?

- Will this pipe system maintain proper pressure?

- Is the cooling system efficient for this engine?

CFD is widely used in:

- Aerospace

- HVAC systems

- Automotive

- Electronics cooling

- Chemical industries

Main Benefits of CFD:

- Visualizes how fluids move

- Helps improve airflow and cooling

- Detects design problems early

FEA or CFD? When to Use Which

The key to choosing between FEA and CFD lies in what you’re testing.

Use FEA when:

- You’re analyzing how strong a part is

- You’re checking for bending, stress, or breaking

- You’re designing solid parts like beams, gears, or casings

Use CFD when:

- You’re dealing with air, water, oil, or any fluid

- You’re studying flow, heat transfer, or cooling

- You’re working on engines, pipes, turbines, or fans

In some cases, you may need both. For example, in a car engine, you use FEA to test if the parts can handle stress, and CFD to check if the cooling system works well.

Why Hexagon Is the Best for Both

Hexagon is a world leader in engineering simulation. They offer advanced software for both FEA and CFD that works for small companies as well as big manufacturers. Their tools are fast, accurate, and easy to use with popular CAD software.

At CreoTek Systems India LLP, we are proud to be a Hexagon Value Added Reseller (VAR). We help Indian companies get the most out of Hexagon’s simulation tools.

Let’s look at Hexagon’s best products for each type of simulation.

Hexagon’s FEA Solution: MSC Nastran & MSC Apex

MSC Nastran is one of the most trusted names in FEA. It’s used by aerospace companies, car manufacturers, and more.

Key Features:

- Handles linear and nonlinear analysis

- Simulates stress, vibration, buckling, and fatigue

- Works with large, complex models

MSC Apex makes it easier to prepare models and do simulation quickly. It has a friendly interface and saves time by automating repetitive steps.

Why Use Hexagon FEA?

- Accurate results trusted by top companies

- Works for metals, plastics, and composites

- Saves time with easy-to-use tools

Hexagon’s CFD Solution: Cradle CFD

Cradle CFD is Hexagon’s tool for fluid simulation. It’s known for being fast and user-friendly, even when handling very large models.

Key Features:

- Simulates airflow, cooling, pressure, and more

- Works with complex geometry

- Offers thermal-fluid analysis in one platform

It is widely used in industries like electronics, automotive, and HVAC.

Why Use Hexagon CFD?

- High-quality visuals help you understand fluid behavior

- Strong performance with large data sets

- Integrated with CAD software for smooth workflow

How CreoTek Helps You Choose

Choosing between FEA and CFD—or knowing if you need both—can be confusing. That’s where CreoTek Systems India LLP comes in.

We help you:

- Understand your project needs

- Pick the right Hexagon tool

- Train your team to use the software

- Get support during and after setup

Whether you’re just starting out or upgrading your simulation process, our team guides you every step of the way. We also help connect simulation tools with your CAD and PLM systems like Creo or Windchill, making everything work together smoothly.

Real Value for Your Business

Using the right simulation tool does more than just speed up development. It also helps you:

- Cut costs by reducing physical testing

- Improve safety by catching design issues early

- Make better products that meet customer needs

- Get products to market faster than competitors

With Hexagon’s advanced tools and CreoTek’s expert support, your company gets the best of both worlds—technology and guidance.

Conclusion

When it comes to product testing and design validation, FEA and CFD are both powerful tools. The right choice depends on your product and what you want to test. FEA is great for solid mechanics, while CFD is best for fluid dynamics.

Hexagon provides top-quality solutions for both. And with CreoTek Systems India LLP as your technology partner, choosing and using the right simulation tool becomes simple, smart, and stress-free.

So whether you’re building a stronger bracket or improving airflow in an engine, we’ve got the right tool—and the right team—for you.