Industry 4.0, a revolutionary stage in the manufacturing industry, is defined by the convergence of digital technology with conventional manufacturing techniques. By creating a networked ecosystem of people, machines, and data, this revolution has unlocked unprecedented opportunities for automation, data-driven decision-making, and innovation. Amid this transformation, CAD (Computer-Aided Design) technologies, such as PTC Creo, have emerged as indispensable tools, bridging the gap between design and manufacturing while adapting to the evolving demands of modern manufacturing.

Industry 4.0: Redefining Manufacturing

At its core, Industry 4.0 integrates advanced technologies like digital twins, augmented reality (AR), artificial intelligence (AI), and the Internet of Things (IoT) into production processes. This confluence enables real-time monitoring, predictive maintenance, enhanced collaboration, and highly customizable manufacturing workflows. Beyond traditional automation, Industry 4.0 introduces interconnected smart factories where processes and systems communicate seamlessly to maximize productivity and efficiency.

The implications for CAD design are profound. Designers today operate in environments that demand optimization for real-time analytics, manufacturing agility, and digital threads. In this landscape, CAD solutions such as PTC Creo lead the evolution of traditional design practices.

CAD for the Industry 4.0 Era: PTC Creo

PTC Creo, a cornerstone of PTC’s portfolio, has evolved to meet the demands of Industry 4.0 with cutting-edge features. It empowers designers and manufacturers in several transformative ways:

Integration of Digital Threads

PTC Creo’s robust integration with PLM (Product Lifecycle Management) platforms facilitates seamless data flow across systems—an essential requirement for Industry 4.0. This integration ensures that designs comply with the latest standards, reducing errors and accelerating time-to-market.

Generative Design

PTC Creo leverages AI to help engineers explore multiple design possibilities within specified parameters. This approach not only fosters innovation but also ensures cost-effectiveness and manufacturability in real-world production scenarios.

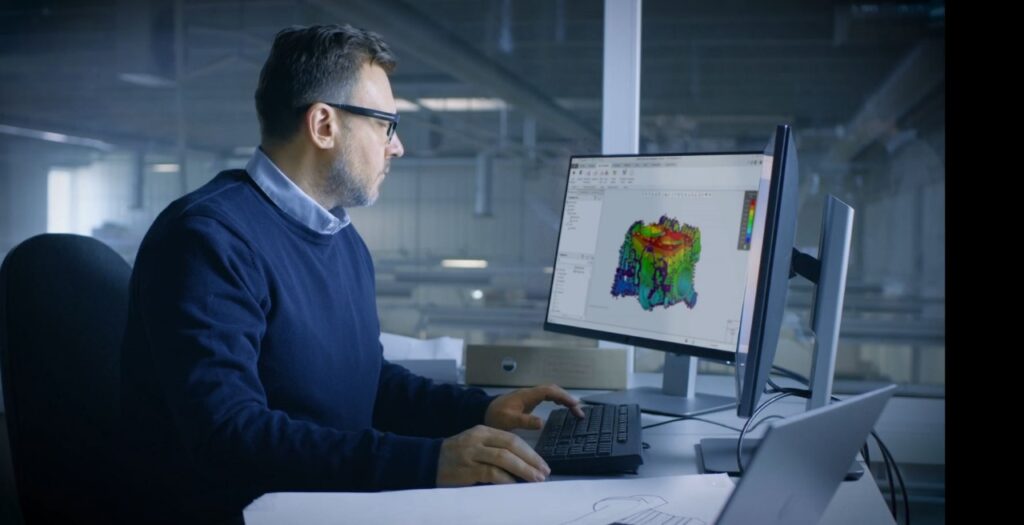

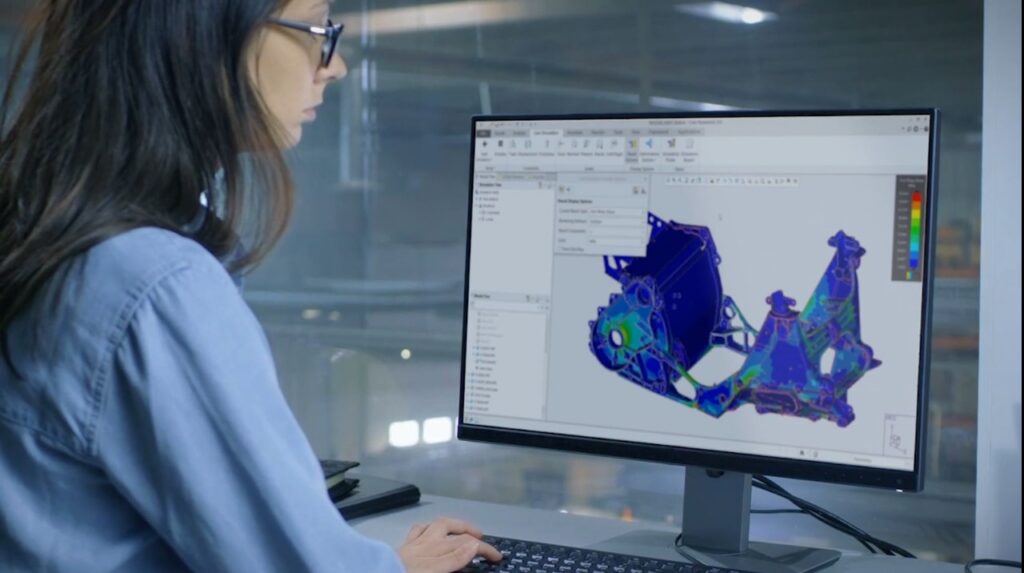

Analysis and Simulation

The advanced simulation capabilities of PTC Creo allow for real-time design testing across various scenarios. By integrating simulation early in the design phase, manufacturers can optimize processes and reduce the need for costly prototypes.

Support for Additive Manufacturing

Additive manufacturing, or 3D printing, plays a crucial role in Industry 4.0’s goal of agile production. PTC Creo supports additive manufacturing directly, enabling designers to create intricate geometries optimized for strength and minimal material waste.

Integration of Augmented Reality

With AR features, PTC Creo enhances collaboration by enabling engineers to visualize designs in real-world environments. This improves stakeholder engagement and expedites decision-making.

The Advantages of CAD and Industry 4.0 Convergence

Integrating Industry 4.0 technologies with CAD tools like PTC Creo offers significant benefits to manufacturers:

Enhanced Efficiency in Design

Automation and AI-powered tools free engineers from repetitive tasks, allowing them to focus on innovation.

Better Collaboration

Technologies like digital twins and AR facilitate better communication among designers, manufacturers, and stakeholders, ensuring alignment throughout the process.

Faster Time-to-Market

PTC Creo’s integration of digital threads and simulation accelerates the design-to-production workflow, enabling swift responses to market demands.

Sustainable Production

Generative design and additive manufacturing minimize material waste, promoting eco-friendly production processes.

Real-World Uses: PTC Creo with Industry 4.0

Consider a scenario where a company needs to design lightweight automotive components. The design team uses PTC Creo’s generative design capabilities to create parts optimized for weight and strength. The design is then virtually tested using simulation tools to ensure performance under stress. Once approved, the design is sent directly to a 3D printer, drastically reducing costs and lead times. Throughout this process, AR visualizations align stakeholders by providing a clear understanding of how the design functions in its intended environment, minimizing the risk of redesigns.

CAD’s Future in Industry 4.0

As Industry 4.0 continues to evolve, CAD tools like PTC Creo will play an increasingly pivotal role in enabling smarter and more adaptable manufacturing. Emerging technologies such as blockchain, cloud computing, and machine learning will further enhance design capabilities, driving innovation to unprecedented levels. The synergy between CAD design and Industry 4.0 will shape a future of sustainable, efficient, and highly personalized manufacturing.

Wrapping Up

The fourth industrial revolution has fundamentally redefined design and manufacturing paradigms, with CAD tools like PTC Creo leading the charge. By embracing the principles of Industry 4.0, manufacturers can unlock new opportunities, turning challenges into competitive advantages. As we move deeper into this transformative era, CAD design powered by Industry 4.0 technologies will remain a cornerstone of innovation in modern manufacturing. With its ability to integrate data-driven insights, foster collaboration, and streamline production workflows, PTC Creo is not just a tool but a strategic enabler, empowering industries to push the boundaries of what’s possible and paving the way for a future defined by efficiency, sustainability, and creativity.

Let’s create something extraordinary together. Get in Touch and discover how CreoTek India can help you turn your vision into reality. The future is waiting—let’s build it!