Introduction

In today’s highly competitive product market, time is one of the most valuable assets a company has. The quicker a company can move from idea to final product, the better its chances of staying ahead of the competition. But speeding up product development is not about rushing-it’s about working smarter. That’s why so many engineering and design teams rely on powerful tools like Creo and Windchill.

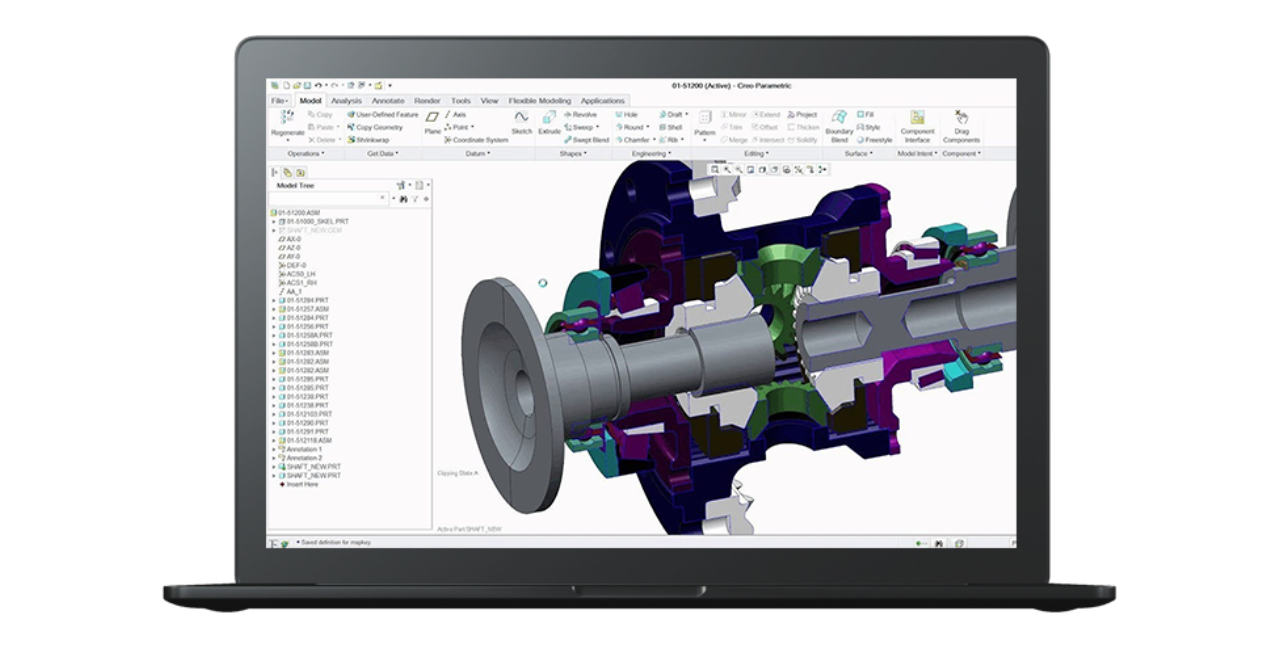

Creo, developed by PTC, is one of the most widely used 3D CAD software tools in the industry. It allows engineers to design high-quality 3D models, run simulations, and make updates easily. Windchill, also from PTC, is a Product Lifecycle Management (PLM) tool. It manages product data, tracks design changes, controls file versions, and connects teams throughout the product lifecycle.

Together, Creo and Windchill create a connected digital environment where teams can collaborate efficiently, reduce delays, and bring products to market faster. In this article, we will explain in simple terms how this combination helps reduce product development time-and why it’s a game-changer for modern manufacturers.

1. Real-Time Collaboration Speeds Up the Entire Process

Traditional product development often involves disconnected teams using different software or systems. Files are shared over email, changes are not tracked properly, and feedback takes days or weeks. All this slows down progress and creates confusion.

With Creo and Windchill, everyone in the organization works from the same digital platform. Designers, engineers, project managers, and even suppliers can access the same version of the design in real-time. Windchill provides a central location for storing all product data, so there is no need to send files manually.

Here’s how it helps:

- Everyone works on the most updated version

- Comments and feedback are stored alongside the design files

- Design changes are visible instantly

- Approvals and reviews happen digitally

This saves time at every stage, especially in large teams working on complex projects. It removes bottlenecks caused by waiting for updates or manually sharing files.

2. Faster and Smarter Design Changes

Changes during product development are inevitable. Sometimes a client changes requirements. Other times, engineers discover a better design or notice an issue. Without the right tools, even small changes can take hours or days to implement.

Creo makes this easier with parametric design. This means that when one part of the model is changed, related parts are updated automatically. You don’t have to manually adjust every component. This drastically reduces the time it takes to revise a design.

On the other hand, Windchill keeps track of every change. It records:

- Who made the change

- When it was made

- What the previous version looked like

This is extremely useful for managing design histories and avoiding repeated mistakes. It also makes audits and compliance checks faster, because everything is documented clearly.

Together, Creo and Windchill ensure that design changes are quick, accurate, and well-documented, keeping development on track.

3. Built-In Simulation Reduces the Need for Physical Prototypes

One of the most time-consuming (and expensive) parts of product development is testing. Traditionally, you have to create physical prototypes to test a product’s strength, heat resistance, or movement. If the prototype fails, you go back to redesigning-and that means more time and cost.

Creo includes built-in simulation and analysis tools, which allow engineers to run digital tests on the design before making any physical model. You can simulate:

- Structural stress and strain

- Heat transfer and temperature effects

- Fluid flow

- Dynamic motion and mechanical performance

These simulations help detect and fix problems early in the design stage. Engineers can try out multiple design ideas quickly, without waiting for prototypes. This improves the quality of the final product while also reducing testing time.

Windchill supports this process by linking the simulation results to the design data. Every test, change, and result is stored in one place, making it easier for teams to review and learn from.

This combination of virtual testing and data management is a major advantage in cutting time and improving reliability.

4. Automatic Data and Document Management Prevents Errors

When you’re working on a complex product, you deal with hundreds-or even thousands-of files. These include CAD drawings, test results, approval forms, bill of materials (BOM), and more. Without a proper system, managing these files becomes chaotic and prone to mistakes.

Windchill takes care of this automatically. It:

- Stores all files in a central, secure system

- Tracks changes and file versions

- Controls access rights so only authorized users can edit data

- Sends notifications for reviews and approvals

Because Windchill is deeply integrated with Creo, engineers don’t need to leave their design environment to manage files. Everything stays organized and up to date in real-time.

This ensures that teams always work with the correct files and documentation, reducing errors that cause delays. It also supports compliance with industry standards and customer requirements.

By keeping product data clean, safe, and accessible, Windchill helps companies avoid costly rework and speed up approvals.

5. Seamless Integration Across Teams Improves Communication

Product development is not just about design-it also includes manufacturing, supply chain, quality control, sales, and marketing. All these departments need access to accurate product information at the right time.

Creo and Windchill offer end-to-end integration, meaning every department can access the same product data without waiting or relying on manual updates.

For example:

- The manufacturing team can plan assembly based on the latest 3D model

- The quality team can check compliance based on actual design specs

- The marketing team can start building product campaigns early using CAD visuals

Windchill ensures that everyone is connected and has access to the right information. There’s no need to request files from the design team or wait for approvals to proceed.

This connected workflow reduces handoff time between departments and minimizes confusion, helping the company move from design to production much faster.

Conclusion

In the modern world of product development, speed is critical-but speed without accuracy is dangerous. That’s why using tools like Creo and Windchill is essential for companies that want to stay competitive.

These tools help teams:

- Collaborate in real time

- Make smart, fast design changes

- Test ideas early with simulation

- Keep product data clean and organized

- Work together across departments

At CreoTek Systems India LLP, we help organizations unlock the full power of Creo and Windchill. Whether you’re designing your first product or managing complex engineering projects, we can help you improve speed, reduce errors, and launch better products-faster.