Thanks to their evolution, engineering simulators now provide exact mechanical system analysis under realistic conditions. Multibody Dynamics (MBD) is one of the most effective motion simulation approaches available.

By anticipating their behavior under different stresses and limitations, this sophisticated approach helps engineers to investigate and maximize difficult mechanical assemblies. MBD enables better general system performance, lower prototyping costs, and design efficiency improvement. Leveraging MBD in motion simulation becomes a vital need for competitive advantage as businesses choose digital transformation methods more and more.

This blog looks at how Multibody Dynamics improves motion simulation, applications, and why engineering companies have to include MBD into their processes.

Recognizing Multibody Dynamics (MBD)

Computationally, Multibody Dynamics (MBD) examines how linked rigid or flexible bodies move in response to applied pressures, torques, and limitations. Unlike conventional static analysis, MBD offers a time-dependent simulation of mechanical systems, therefore enabling engineers to see and comprehend dynamic interactions in machines, vehicles, and industrial equipment.

An MBD system comprises several components, including:

Mechanical components expressed by rigid and flexible bodies

- Joints and restrictions specifying body connectivity

- External forces including touch, friction, and gravity

- Control inputs including sensors and actuators

Incorporating Newtonian physics and numerical solvers, MBD program forecasts real-world mechanical motion, therefore enabling engineers to find possible design defects early in the course of development. Industries like automotive engineering, aerospace, and robotics—where motion accuracy is absolutely vital—will find this predictive power very helpful.

Main advantages of applying MBD in motion simulation

Enhanced Design Accuracy: By use of MBD, engineers may evaluate product performance in real-world environments, therefore enabling more accurate mechanical motion forecasts. This accelerates the development process in addition to lessening the required number of design changes.

Using virtual testing through MBD helps to remove the need for many physical prototypes, therefore saving time and money. Instead of laborious trial-and-error, engineers can alter designs depending on simulation findings.

Precision changes to system dynamics made possible by MBD increase mechanical component dependability, efficiency, and durability. It lets engineers maximize part lifetime, load distribution, and energy use.

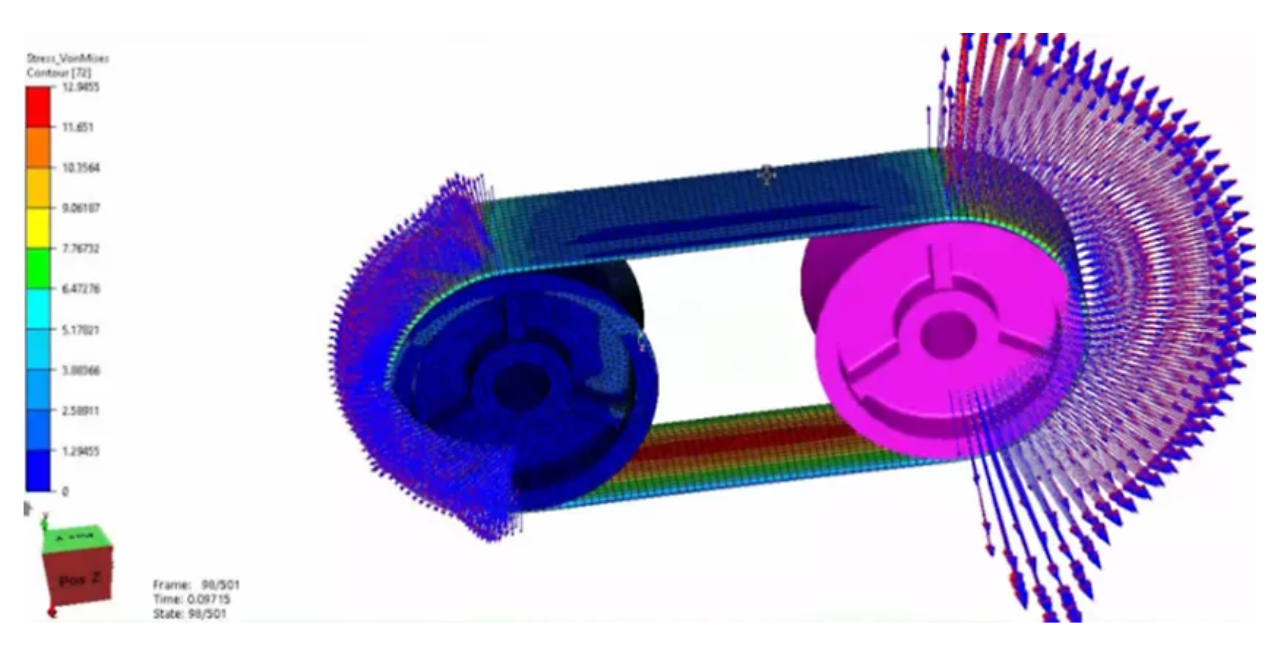

Dynamic simulations help to identify weak points in a system, so addressing possible faults before manufacturing starts. Engineers can predict in mechanical assemblies stress distribution, fatigue sites, and failure modes.

Perfect Integration with Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA): MBD presents engineers with a whole picture of performance and works wonderfully with other simulation techniques. Combining MBD with FEA and CFD helps to create multi-disciplinary simulations improving design validation.

Let us explore Model-Based Design’s (MBD) engineering applications:

1. Automotive Industry

Manufacturers in the automobile industry are using MBD to replicate anything from vehicle dynamics and suspension behavior to collision situations and drivetrain performance. Predicting how various parts would interact on different road surfaces helps engineers improve safety and fine-tune ride quality. Furthermore, MBD transforms the field of building autonomous vehicle control systems by enabling realistic simulations of sensor reactions and motion behaviors.

2. Aerospace Engineering

In the field of aeronautical engineering especially for structural dynamics, flight control systems, and aircraft landing gear design, MBD is crucial. Engineers can greatly increase safety and efficiency by studying aircraft movement under demanding circumstances. To guarantee dependability, they can replicate landing impacts, turbulence, even mechanical system redundancies.

3. Robotics and Automation

Designing robotic systems benefits much from MBD’s ability to maximize kinematics and dynamic motion. MBD simulations are the tool engineers use to design industrial robots with exact movement and collision avoidance. Smoother manufacturing and logistical automation follows from this.

4. Industrial Equipment and Heavy machinery

Heavy machinery including cranes, excavators, and several manufacturing machines finds great application for MBD. It facilitates load-bearing capacity analysis and component wear-down prediction under actual conditions. This method not only lowers maintenance expenses but also increases equipment lifetime.

5. Medical Devices and Biomechanics

In the field of biomechanics and medical devices, MBD is absolutely essential in mimicking joint motions, muscle forces, and orthopedic implants. This technology opens the path for improved patient medical solutions. Engineers use MBD to create prosthesis that replicate natural motion and to investigate ergonomics, enhancing human interaction with machines.

How Engineering Companies Could Perfectly Include MBD Into Their Processes

First step: choose appropriate MBD program

For MBD simulations, there are a number of programs like Simcenter 3D, MSC Adams, and PTC Creo. To maximize throughput, choose a platform that fits your present CAD and FEA tools.

Second Step: Creating Correct Models

Engineers must create thorough mechanical models including exact definitions of rigid and flexible bodies, limitations, and force interactions. The simulation accuracy improves with increasing precision of the models. Results can be much improved by using accurate material attributes and high-resolution meshing.

Running simulations and analyzing results comes in third.

Real-time motion analysis provided by MBD simulations lets engineers adjust settings, improve designs, and lower risk of failure before manufacturing starts. All inside a virtual reality, they may see motion pathways, force distributions, and interaction impacts.

Fourth step: iterating and optimizing

Multiple iterations of MBD simulations allow engineers to fine-tune mechanical systems to attain ideal performance, durability, and economy of cost. Designed improvements for optimal efficiency can be automated with the help of the optimization algorithms included into MBD tools.

Conclusion:

Multibody dynamics (MBD) is transforming mechanical system motion simulation and analysis by engineers. Companies can improve design correctness, performance, and cost savings by including MBD into their engineering processes.

Using modern MBD technologies will be essential to keep ahead of the competition as sectors keep embracing digital engineering. Engineering companies ready to improve their motion simulation capacity should investigate MBD solutions meeting their particular needs. Future motion simulation using MBD is set to be more exact, efficient, and creative than it has ever been