Introduction

Organizations in a competitive manufacturing environment search continuously for techniques and technologies that guarantee product dependability and lower development costs. One such very effective instrument is finite element analysis (FEA). From aerospace and automotive to industrial design and consumer items, it is essential in maximizing product designs before they ever reach the manufacturing stage. By increasing lifespan prediction and material efficiency, our sophisticated FEA solutions at CreoTek Systems India LLP are revolutionizing how businesses approach product development.

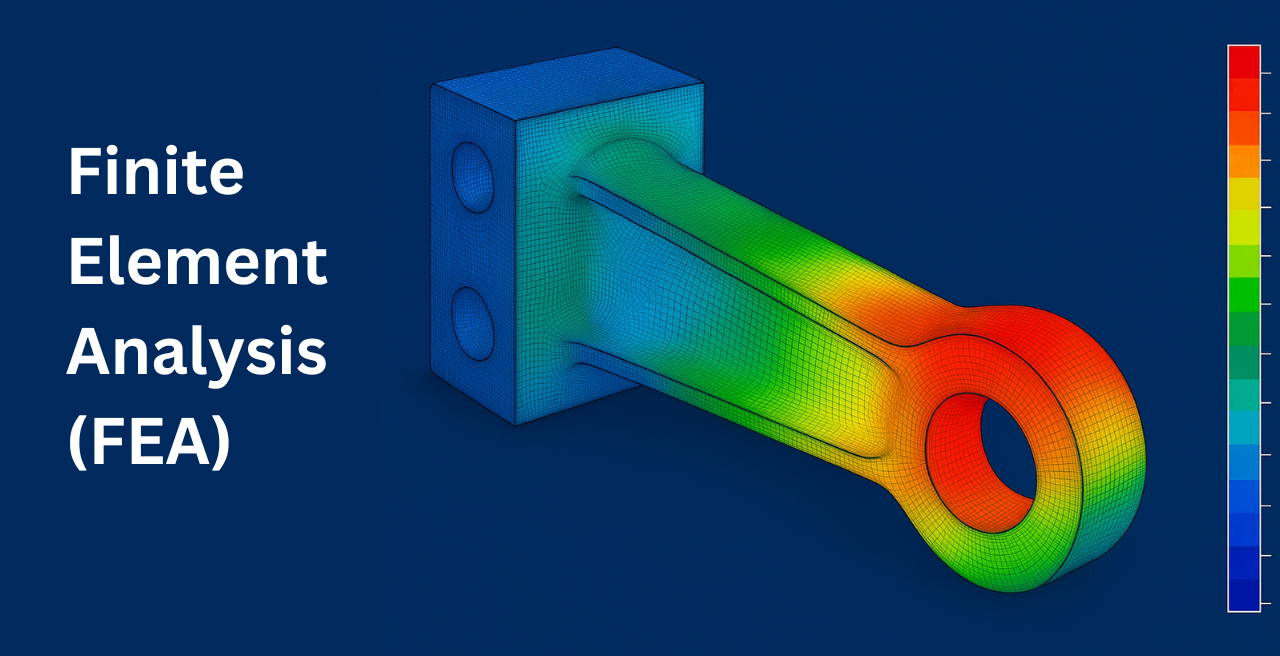

Understanding Finite Element Analysis (FEA)

A computer-based simulation method called finite element analysis (FEA) helps one forecast a product’s response to real-world stresses. It measures structural integrity, thermal performance, fluid flow, and other physical influences. Engineers replicate stress, strain, deformation, and temperature distribution in the design by breaking up a complicated object into smaller, controllable sections called finite elements.

This study offers insightful information throughout the design stage, therefore saving the need for expensive physical prototypes and iterations. Using cutting-edge FEA tools, we at CreoTek assist customers in understanding and improving their products prior to mass production.

FEA for Forecasting Product Lifespan

Maintaining consumer happiness and durability of a product depends on an awareness of its lifetime. By modeling wear, fatigue, and other long-term consequences of frequent usage or environmental stress, FEA is indispensable in forecasting longevity.

Examining Fatigue

Most mechanical failures have fatigue as their cause. FEA finds zones of stress concentration where fatigue cracks might start. Engineers can project the number of cycles a product can withstand before failure by modeling repeated loading circumstances. This lets designers improve durability, fix weak points, and lower warranty claims.

Creep and Thermal Degradation

In applications under steady pressure or heat, creep starts to cause problems. FEA predicts temperature with time, so enabling the evaluation of thermal degradation in materials like plastics, metals, and composites. Electronics and aerospace sectors’ manufacturers mostly depend on this capacity to create parts with extended lifetime of operation.

Corrosion and Environmental Consequences

FEA also helps assess how external elements including UV exposure, moisture, and chemicals could influence product lifetime. Simulating material behavior under these conditions helps businesses make decisions on coatings, treatments, and material choice.

FEA to Control Material Costs

Material use is among the most important cost factors in product manufacturing. Underdesign runs the danger of failing; overdesign adds weight and cost. FEA helps businesses find the ideal mix between cost-effective materials and strength.

Structural Optimization

FEA helps find extraneous material in non-critical parts of a component. Companies save on materials by developing these lighter regions without sacrificing structural integrity. In fields like automotive and aerospace, where every gram counts for fuel economy and compliance, this is extremely helpful.

Optimization of Topology

Engineers build organic, weight-efficient structures using FEA-driven topology optimization. This methodology allows designs that would be unfeasible or unworkable with conventional techniques. Combined with modern CNC machining or 3D printing, this produces creative, reasonably priced components.

Material Exchange

FEA simulations evaluate several loads and circumstances’ performance of different materials. This helps businesses to move to more reasonably priced or environmentally friendly materials without first-hand experience testing. Changing from metal to high-strength polymer composites, for instance, might cut weight and cost—all confirmed by simulation.

FEA in Use Across Fields of Industry

FEA isn’t confined to one sector either. Its uses guarantee efficiency, compliance, and product safety across several industries.

Auto Sector

In vehicle design, FEA tests fatigue resistance, vibration, and crashworthiness. It lets engineers test thinner materials or alternative alloys without sacrificing safety criteria, therefore supporting light weight techniques.

Consumer Gadgets

By use of thermal and structural examination of circuit boards and casings, one guarantees that gadgets stay safe and functional even under great use or environmental stress. FEA simulations increase product lifetime and help to lower overheating concerns.

Industry Machinery

Large machinery has to bear constant loads and great stress. FEA helps companies to forecast wear spots and redesign components for reduced replacement costs and increased lifetime.

FEA Solutions: The CreoTek India Advantage

Leading FEA solutions catered to particular business requirements come from CreoTek Systems India LLP. Modern simulation tools are used by our team of professionals to provide precise, perceptive analysis improving cost-efficiency and product performance.

From modeling to optimization, we provide end-to-end solutions covering manufacturing, energy, consumer products, and automotive sectors. The following main pillars form the foundation of our process:

High-fidelity models guarantee practical applicability.

Quick simulations cut design cycles.

Deep knowledge of mechanical behavior guarantees wise conclusions.

Customizing solutions is based on particular industry norms and corporate requirements.

For seamless processes and quicker innovation, our FEA solutions are coupled with other engineering technologies including CAD and PLM.

FEA Benefits for Teams Working on Product Development

Early FEA implementation by businesses results in major benefits spanning the product life:

Accelerated Time to Market

Early design faults let for faster fixes and help to lower the demand for actual prototypes. This quickens time-to- market and accelerates product development.

Lowered Warranty Claims

Precise lifetime prediction and identification of failure modes guarantees strong goods. Higher customer satisfaction and reduced returns or repair requests follow from this.

Reduced Manufacturing Cost

Effective manufacturing processes with less waste, less material consumption, and fewer labor expenses follow from optimized designs. Over the lifetime of the good, these savings accumulate.

Improved Originality

Accurate simulations give design teams confidence to push limits, test unusual materials, and create innovative products.

Conclusion

Modern product development cannot afford to overlook FEA as a vital instrument. It enables businesses to create leaner, smarter designs, and better-performance goods via means of manufacturing. From cost savings to customer delight, it delivers value everywhere by precisely forecasting lifespan and optimizing material use.

Our technical specialty at CreoTek Systems India LLP is providing innovative FEA tools that match engineering accuracy with corporate objectives. Whether you’re designing a light-weight automobile part or streamlining a difficult industrial assembly, our solutions will enable you to design with assurance and lead with creativity.