FTI Sheet Metal Forming Simulation

A specialized software program for sheet metal forming, from costing to design and production, is called FTI FormingSuite.

Engineers and manufacturers may model and evaluate the sheet metal forming process with the help of Hexagon MSC’s robust software solution, FTI Sheet Metal Forming Simulation. It provides an extensive feature set and tool set created especially for metal forming operation simulation and optimization.

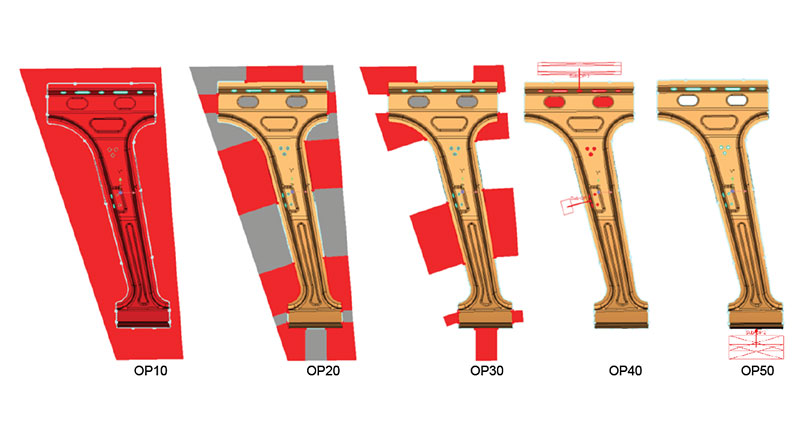

Users may forecast and assess how sheet metal will behave throughout the forming process with the help of FTI Sheet Metal Forming Simulation. It uses sophisticated algorithms and material models to forecast crucial events like thinning, wrinkles, and springback with accuracy. Engineers can forecast possible faults, optimize die designs, and make well-informed decisions to increase production efficiency by modeling the forming process.

The program offers an intuitive user interface that makes the process of designing simulations and interpreting the outcomes easier. It provides complete post-processing tools, sophisticated material modeling, and strong meshing capabilities. To learn more about the forming process, users may see and examine the distribution of stresses, strains, variations in thickness, and other factors.

In sectors where sheet metal forming is essential to component manufacture, such consumer products, automotive, and aerospace, FTI Sheet Metal Forming Simulation is extensively utilized. It assists producers in cutting down on expensive trial-and-error procedures, minimizing waste, enhancing part quality, and maximizing production cycle times.

For engineers and manufacturers looking to improve the productivity, precision, and profitability of their sheet metal forming processes, FTI Sheet Metal Forming Simulation is a useful tool. They may use it to forecast and reduce forming faults, improve designs, and eventually produce and market high-quality goods.