In today’s fast-paced industrial world, product development is becoming increasingly complex. Teams are expected to innovate rapidly, reduce costs, and maintain quality while working across different systems and geographies.

Still, one major obstacle remains: data silos. Design engineers use CAD tools, analysts rely on CAE software, and managers track processes through PLM systems. When these devices do not communicate effectively, productivity suffers.

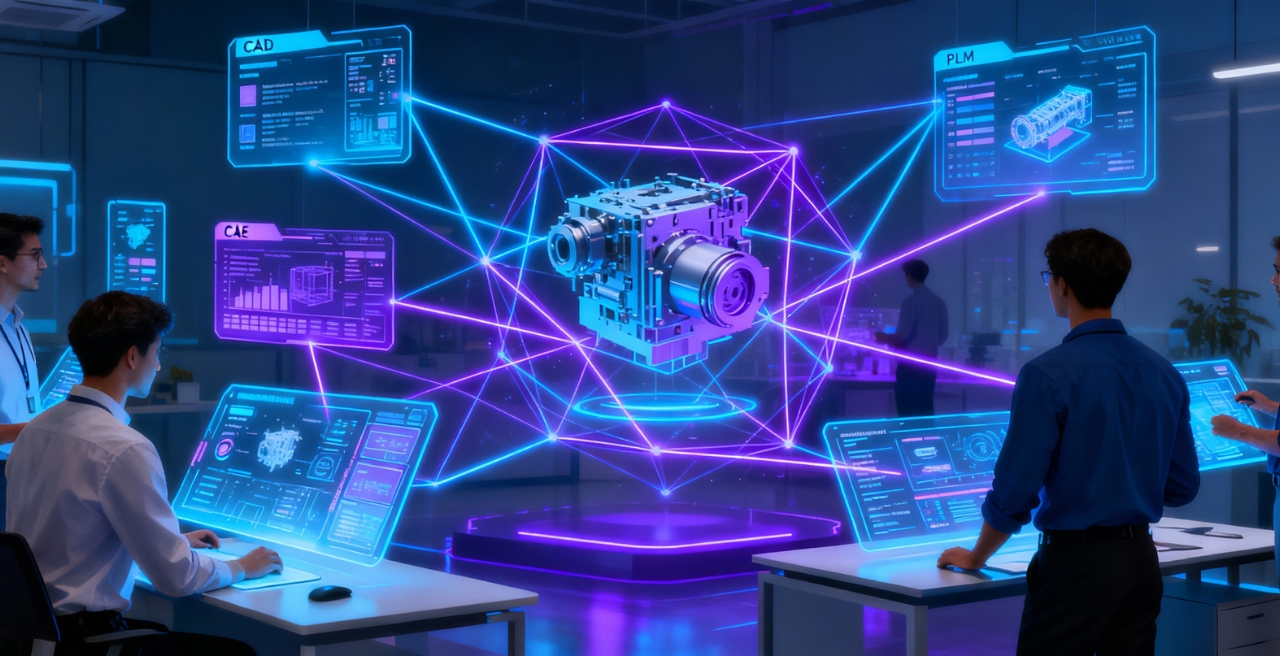

An integrated digital engineering ecosystem connecting CAD, CAE and PLM can change this reality. It streamlines collaboration, ensures data consistency, and accelerates innovation from concept to production.

Understanding CAD, CAE, and PLM

Each tool plays a vital but distinct role in the engineering workflow:

- CAD (Computer-Aided Design): Used for 2D and 3D modeling, detailing, and design creation.

- CAE (Computer-Aided Engineering): Enables simulation and analysis to virtually test product performance.

- PLM (Product Lifecycle Management): Manages product data, revisions, and workflows across the entire lifecycle.

While each system adds value individually, disconnected workflows often lead to duplicate data, version mismatches, and communication gaps. Integration is the key to turning these devices into a single, intelligent ecosystem.

Why Integration Matters

Without integration, product teams face multiple challenges:

- Frequent manual file transfers occurring between different systems.

- Modifications in design that do not appear in simulation models.

- Wasted time in monitoring versions and obtaining approvals.

- Discrepancies in data among various departments.

The integration of CAD, CAE, and PLM bridges these gaps. This establishes a single source of truth, ensuring that design, analysis, and lifecycle data are always synchronized and accessible.

Benefits of a Unified Digital Engineering Ecosystem

A seamlessly integrated system provides considerable business and technical benefits:

Faster Product Development: Real-time updates between design and analysis eliminate delays and rework.

Better accuracy: Automatic synchronization ensures that simulations always reflect the latest design iterations.

Advanced Collaboration: Design, analysis, and manufacturing teams can access shared data in a controlled environment.

Low cost: Reducing unnecessary tasks and physical prototyping saves time and resources.

Making Better Decisions: With connected data and insights, engineers can optimize designs early in the process.

Integration ultimately changes product development from a linear process into an ongoing digital feedback loop.

How Integration Works

There are several ways that organizations integrate CAD, CAE, and PLM systems:

API and Connectors: Many modern tools support data exchange and process automation directly through APIs.

Centralized Data Repository: All files, metadata, and versions are stored in a single managed location.

Cloud-Based Platform: These enable real-time collaboration and global data access, ensuring everyone works with the latest models.

Integration guarantees that any changes made to the design are automatically reflected in the simulation inputs and PLM records, thereby preserving complete design intent and traceability.

Overcoming Integration Challenges

Although the benefits are obvious, integration can present practical obstacles:

- Different file formats: Legacy systems often use incompatible file types.

- Data security: Sharing data across connected systems requires strong access controls.

- Complex IT infrastructure: Older systems may require upgrades or replacement.

- Change management: Engineers must adopt new processes and tools.

Best Practices:

- Start with a clear migration and integration roadmap.

- Conduct pilot projects to validate data flow and performance.

- Provide cross-functional training to ensure adoption.

- Continuously monitor and document integration processes.

Systematically addressing these challenges guarantees a seamless transition to a cohesive environment.

The Future of Digital Engineering Integration

Integration is also evolving along with digital transformation trends.

Emerging technologies are expanding possibilities:

- Cloud-native CAD and simulation: real-time collaboration and version control.

- AI-powered design optimization: Intelligent automation for faster decisions.

- Digital Twins: Real-time synchronization of physical and digital models for predictive insights.

These innovations are driving Industry 4.0, where digital continuity in design, simulation and lifecycle management is the norm rather than the goal.

Conclusion

The integration of CAD, CAE, and PLM transcends a mere technical enhancement – it represents a strategic investment in both innovation and efficiency.

By creating a unified digital engineering ecosystem, organizations can:

- Accelerate the design-to-production cycle.

- Minimize development risks.

- Increase collaboration across teams and locations.

As industries continue their journey towards digital transformation, the ability to seamlessly connect design, analytics and lifecycle data will define the most competitive and forward-looking engineering enterprises of the future.