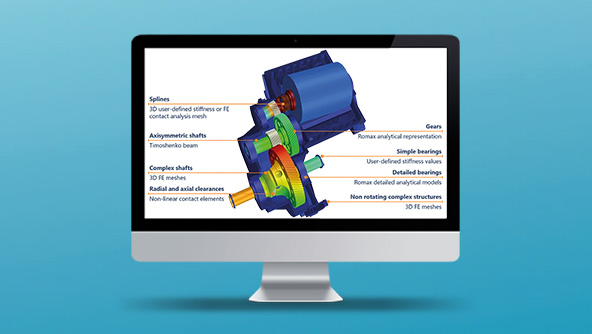

The Romax Technology, now known as Hexagon’s Romax, is a leading provider of software solutions for engineering design, analysis, and simulation of drivetrains and rotating machinery. Romax offers a range of tools and services for industries such as automotive, wind energy, aerospace, and marine. Their software solutions cover areas such as gearbox design, bearing analysis, driveline optimization, and durability assessment. Romax’s expertise in drivetrain engineering helps organizations improve efficiency, reliability, and performance of their mechanical systems. With their advanced simulation capabilities and extensive industry experience, Romax has established itself as a trusted partner for companies looking to enhance the design and performance of their drivetrain and rotating machinery applications.

Romax Enduro

Romax Enduro is a durability and structures software that enables electro-mechanical powertrain durability simulation.

Romax Spectrum

Romax Spectrum is a noise and vibration (NVH) simulation software that enables electro-mechanical powertrain NVH simulation.

Romax Spin

Romax Spin is a dedicated bearing analysis software that enables advanced simulation of rolling element bearings.

Romax Concept

Romax Concept is a concept design software that allows early-stage investigation of EV drivetrain designs.

Romax Energy

Romax Energy is an efficiency and thermal software that predicts electro-mechanical transmission efficiency.

Romax Evolve

Romax Evolve is an electric machine simulation software that enables structural design and analysis of electrical machines.

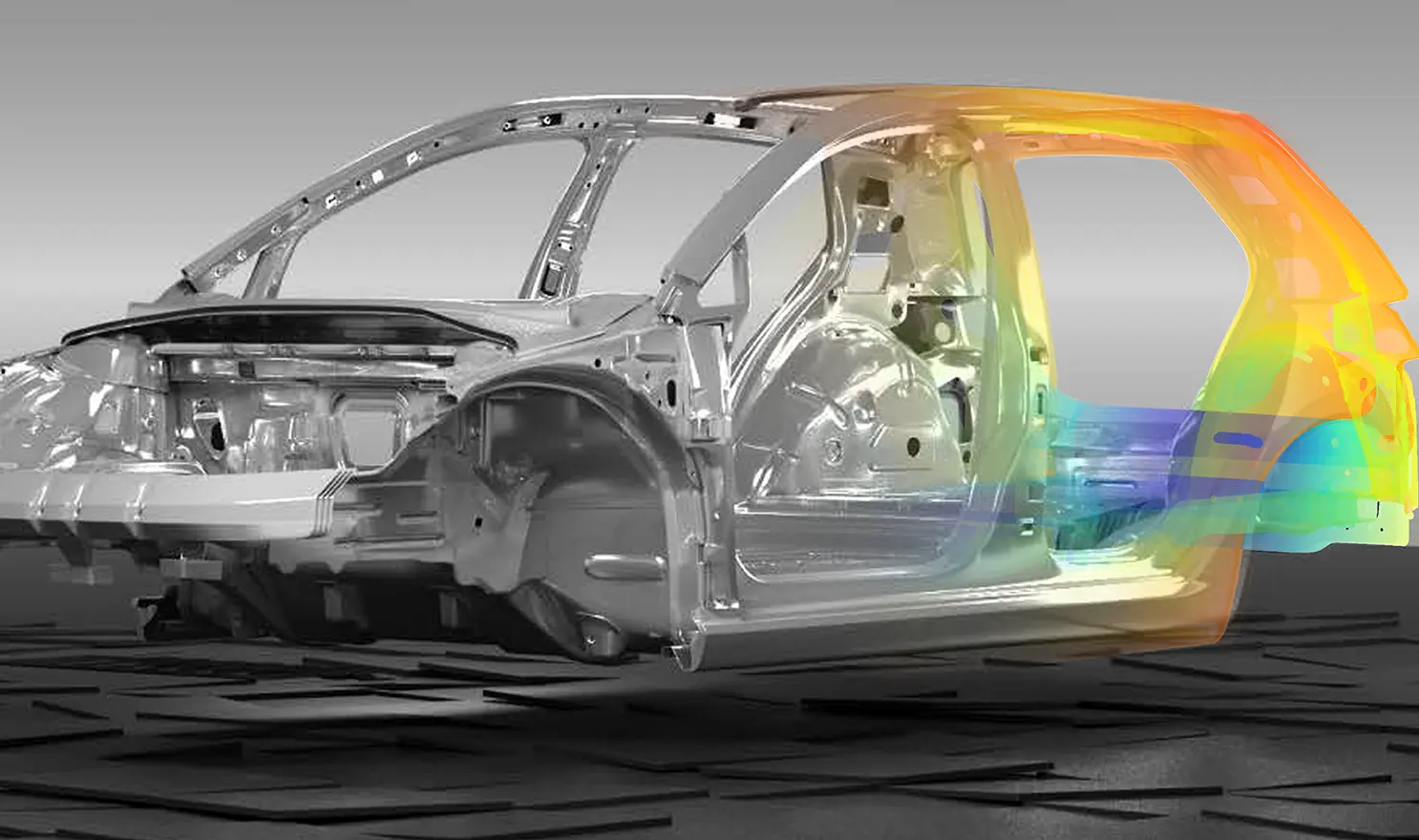

Marc is a powerful nonlinear finite element analysis (FEA) software developed by Hexagon’s MSC Software. It specializes in simulating and analyzing complex nonlinear behavior in structures and materials. Marc offers advanced capabilities for modeling and analyzing phenomena such as large deformations, material nonlinearities, contact interactions, and multiphysics coupling.

The software is widely used in industries such as automotive, aerospace, civil engineering, and manufacturing for a range of applications including structural analysis, crashworthiness, metal forming, and durability assessment. With its robust solver technology and comprehensive features, Marc enables engineers to accurately predict and understand the behavior of structures and materials under various loading and environmental conditions.

These include:

- Nonlinear analysis that incorporates all forms of nonlinearities (Material, geometric, boundary condition including contact)

- Thermal analysis

- Coupled thermomechanical analysis

- Electromagnetics

- Piezoelectric analysis

- Electrical-Thermal-Mechanical

- Electrostatics and Magnetostatics coupled with structural response

- Manufacturing processes like sheet metal forming, hydroforming, extrusion, blow molding, welding, quenching, curing, cutting etc.

- Piezoelectric analysis with higher order 3D elements

Simufact is a leading provider of simulation software for manufacturing processes. Their software solutions enable engineers and manufacturers to simulate and optimize metal forming, welding, additive manufacturing, and machining processes. Simufact’s simulation tools accurately predict the behavior of materials and components during manufacturing, helping to optimize process parameters, minimize defects, reduce costs, and improve product quality. With a focus on the metalworking industry, Simufact serves a wide range of sectors including automotive, aerospace, energy, and medical. Their advanced simulation capabilities and user-friendly interfaces make Simufact a trusted partner for organizations seeking to enhance their manufacturing processes and achieve greater efficiency and competitiveness.

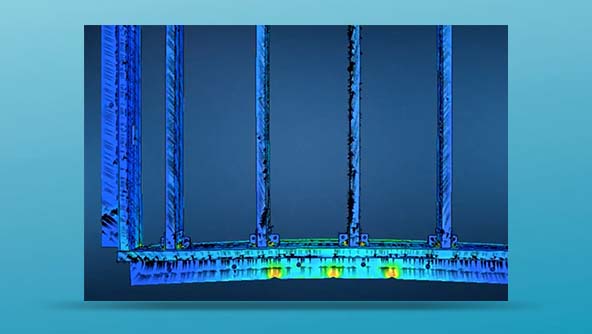

Simufact Forming is an established software solution for the simulation of metal forming manufacturing processes. The software covers all essential areas of forming technology: forging, cold forming, sheet metal forming, all major incremental processes and mechanical joining. Simufact Forming provides support in microstructure simulation, calculation of die load, material flow and prediction of material properties in the course of conventional and inductive heat treatment. Furthermore, thermo-mechanical joining methods of pressure welding are also supported.

Click here to learn more about Simufact Forming.

Simufact Welding is used for modelling and optimising a wide range of fusion and pressure welding processes, taking into account weld sequence and clamping. Processes such as arc welding, laser beam welding, electron beam welding, brazing, resistance spot welding as well as the generative manufacturing process ‘Direct Energy Deposition’ (DED or WAAM) can be modelled in Simufact Welding. Additionally, Simufact Welding can be used to model the heat treatment, different variants for cooling and unclamping as well as the mechanical load on welded structures.

Click here to learn more about Simufact Welding.

Simufact Additive is a scalable software solution for the simulation of metal-based additive manufacturing processes which focuses on powder bed melting (L-PDF) and metal binder jetting (MBJ) processes. Simufact Additive is a software solution designed to predict and compensate for distortion, residual stress and temperature distribution throughout the printing, heat treatment, cutting, hot isostatic pressing (HIP) as well as machining processes virtually before the part is manufactured by the 3D metal printer in reality.

Click here to learn more about Simufact Additive.

Digimat is a sophisticated material modeling and simulation software developed by e-Xstream Engineering, a subsidiary of Hexagon’s MSC Software. It specializes in virtual material engineering and allows engineers to accurately predict and optimize the behavior of composite materials. Digimat combines advanced material modeling techniques with finite element analysis (FEA) to simulate the complex behavior of composite structures under various loading conditions. The software enables users to analyze the mechanical properties, durability, and crashworthiness of composite materials, leading to improved design optimization, reduced development time, and enhanced product performance. Digimat is widely used in industries such as automotive, aerospace, and consumer goods where composite materials play a crucial role in lightweighting, durability, and energy absorption.

Digital materials laboratory

Accelerate material innovations while minimizing physical testing and saving development time & cost.

Multiscale simulations

Enrich CAE analyses by intrinsically connecting the manufacturing process, material properties and part performance.

Polymer additive manufacturing

Reduce hundreds of trials and errors in a couple of clicks to optimise productivity and part performance.

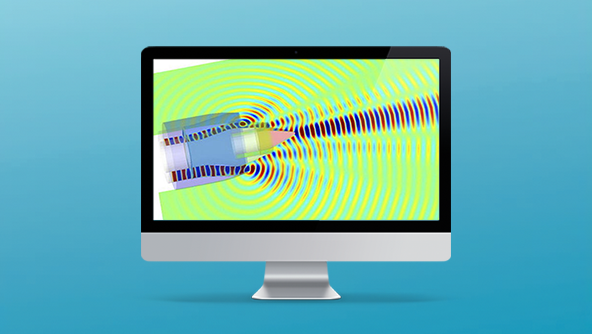

Actran Acoustics is a powerful software solution developed by MSC Software for simulating and analyzing acoustic phenomena. It is widely used in industries such as automotive, aerospace, and consumer electronics to optimize the acoustic performance of products and systems. Actran Acoustics offers comprehensive capabilities for modeling and analyzing sound propagation, noise generation, and sound transmission. It allows engineers to accurately predict and evaluate the acoustic behavior of complex structures, such as vehicle cabins, aircraft interiors, and electronic devices. he software supports a wide range of acoustic simulations, including interior and exterior noise, sound quality analysis, vibro-acoustic coupling, and aeroacoustics. Actran Acoustics utilizes advanced algorithms and numerical techniques to provide accurate results and facilitate detailed analysis. Its user-friendly interface, extensive material library, and robust solver technology make it a valuable tool for engineers seeking to optimize acoustic performance, reduce noise levels, and improve the overall acoustic comfort and quality of their products.

Simulate standard and convected acoustics

- Extract acoustic modes

- Analyze sound field in cavities, with either modal or physical approaches

- Model absorbing walls using impedance conditions of porous material models

- Analyze sound radiation

- Analyze sound propagation in ducts, intake and exhaust lines or distribution systems in buildings, aircrafts, and automobiles

- Recover vibration results from most FEA structural solvers for radiation analysis

Actran VibroAcoustics

Actran VibroAcoustics is a robust, reliable and high-performing vibro-acoustic CAE module.

Actran AeroAcoustics

Actran AeroAcoustics predicts the noise generated by complex flows.

Actran SNGR

Actran SNGR predicts the noise generated by complex flows from steady CFD solutions.

Actran DGM

Actran DGM predicts model noise propagation in complex flows.

Actran for Trimmed Body

Actran for Trimmed Body performs advanced vibro-acoustic analysis, combining Actran and MSC Nastran.

Actran SEA

Actran SEA is an efficient mid- and high- vibro-acoustic CAE module.

Actran TM

Actran TM is a CAE tool for turbomachinery noise prediction.

Actran VI

Actran VI is a graphical user interface for pre- and post-processing vibro- and aero-acoustic analyses of all Actran modules.

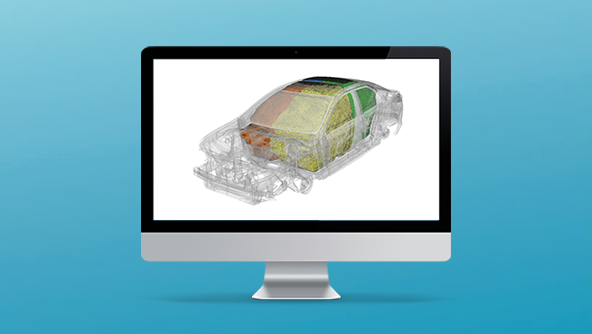

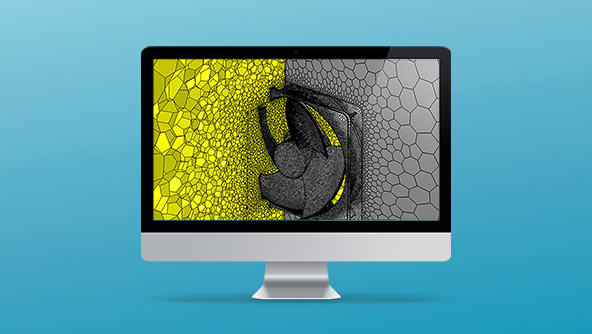

Cradle CFD is a comprehensive computational fluid dynamics (CFD) software package developed by Hexagon MSC. It provides engineers and designers with a powerful toolset for simulating and analyzing fluid flow, heat transfer, and related phenomena in various industries.

Cradle CFD offers a range of advanced simulation capabilities, including steady-state and transient analysis, turbulence modeling, multiphase flow, combustion analysis, and more. The software supports a wide range of applications, such as automotive aerodynamics, HVAC design, chemical processes, and environmental analysis.

One of the key strengths of Cradle CFD is its user-friendly interface and intuitive workflow. It provides a seamless and efficient user experience, allowing engineers to set up, solve, and post-process simulations with ease. The software also includes advanced meshing capabilities for generating high-quality meshes, which are crucial for accurate and reliable results.

Cradle CFD offers a range of specialized modules and solvers to cater to specific industry needs. These include SC/Tetra for complex geometries, SC/Tetra Parallel Processing for high-performance computing, scSTREAM for thermal analysis, and more.

Additionally, Cradle CFD provides comprehensive post-processing and visualization tools that enable engineers to analyze and interpret simulation results effectively. It allows users to visualize flow patterns, temperature distributions, and other important parameters through detailed graphs, contour plots, and animations.

With its robust capabilities, user-friendly interface, and specialized modules, Cradle CFD is a trusted choice for engineers and designers seeking accurate and efficient simulations to optimize their designs, improve product performance, and make informed engineering decisions.

Cradle CFD scFLOW

Cradle CFD scFLOW is a thermo-fluid analysis system with polyhedral mesh.

Cradle CFD SC/Tetra

Cradle CFD SC/Tetra is a general-purpose thermo-fluid analysis system with unstructured mesh.

Cradle CFD scPOST

Cradle CFD scPOST is a comprehensive and versatile data visualisation software.

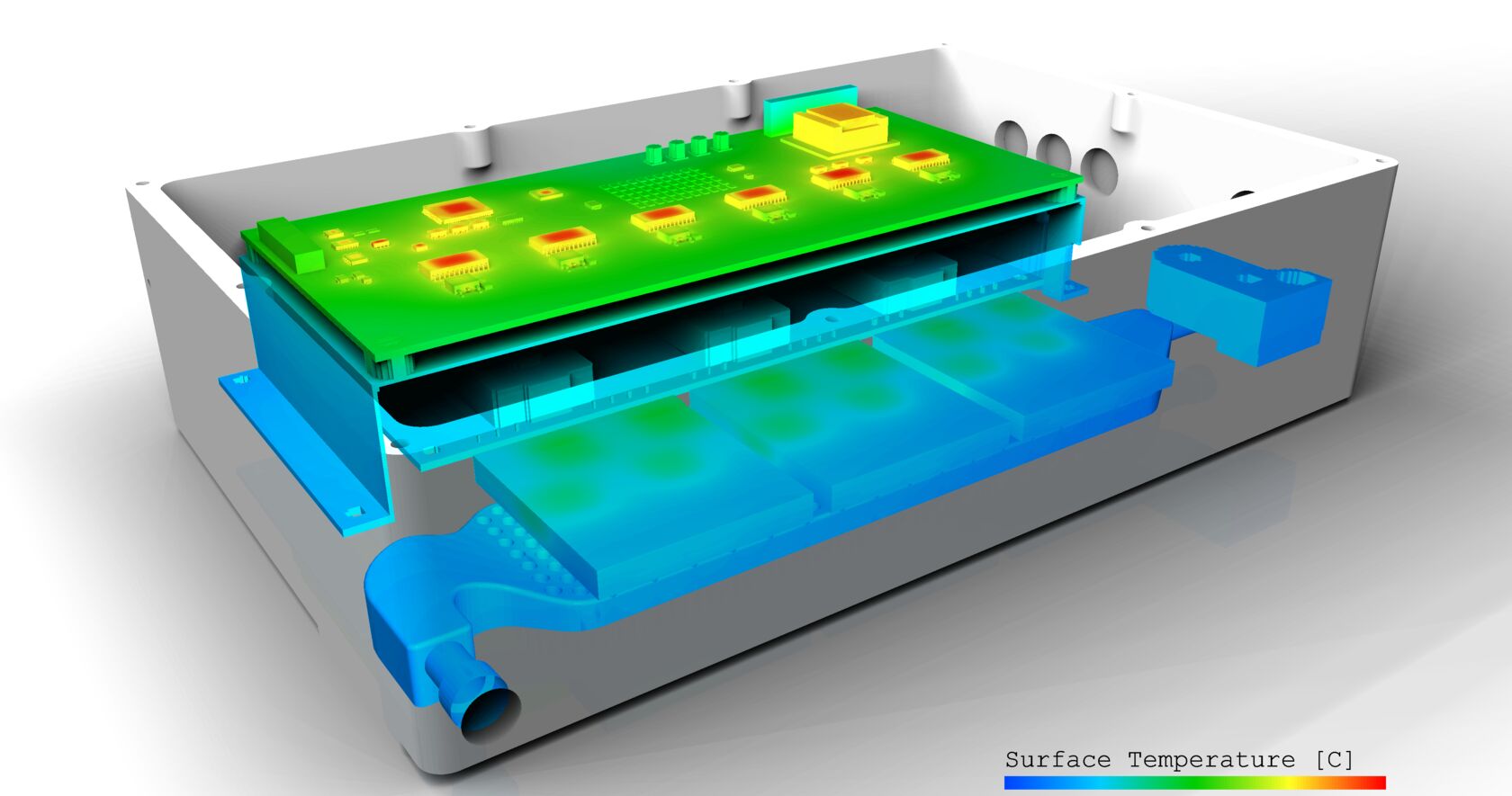

Cradle CFD scSTREAM

Cradle CFD scSTREAM is a general-purpose thermo-fluid analysis system with structured mesh.

Cradle CFD PICLS

Cradle CFD PICLS is a tool for real-time thermal simulation of printed circuit boards.

FTI Sheet Metal Forming Simulation, developed by Hexagon MSC., is a powerful software solution that enables engineers and manufacturers to simulate and analyze the sheet metal forming process. It offers a comprehensive set of tools and features specifically designed for the simulation and optimization of metal forming operations.

FTI Sheet Metal Forming Simulation allows users to predict and evaluate the behavior of sheet metal during the forming process. It incorporates advanced algorithms and material models to accurately predict springback, wrinkles, thinning, and other critical phenomena. By simulating the forming process, engineers can optimize die designs, predict potential defects, and make informed decisions to improve production efficiency.

The software provides a user-friendly interface that simplifies the process of setting up simulations and analyzing results. It offers robust meshing capabilities, advanced material modeling, and comprehensive post-processing tools. Users can visualize and analyze the distribution of strains, stresses, thickness variations, and other parameters to gain insights into the forming process.

FTI Sheet Metal Forming Simulation is widely used in industries such as automotive, aerospace, and consumer goods, where sheet metal forming plays a crucial role in component manufacturing. It helps manufacturers reduce costly trial-and-error processes, minimize scrap, improve part quality, and optimize production cycle times.

Overall, FTI Sheet Metal Forming Simulation is a valuable tool for engineers and manufacturers seeking to enhance the efficiency, accuracy, and profitability of their sheet metal forming operations. It enables them to optimize designs, predict and mitigate forming defects, and ultimately deliver high-quality products to the market.

Design everything, Simulate anything with MSC One Software

MSC One is a flexible and expanded product software solution that lets you take advantage of the broad range of MSC Software’s simulation portfolio within a token-based licensing system.

Purchased as an annual subscription, MSC One provides a cost-effective investment in product development giving access to a suite of multidisciplinary engineering software tools.

MSCOne now includes access to our e-learning platform so you can develop new skills and simulate more – anytime, anywhere.

The benefits of MSCOne

- Accelerate innovation in your product line by taking advantage of simulation solutions that your company did not have access to previously.

- Improve productivity and create a flexible environment, as your project and CAE needs mature or change.

- Reduce financial risk with the ability to increase or decrease capacity as your engineering needs change.

- Reduce cost and access infrequently used CAE applications that might otherwise be difficult to justify commercially. Consolidate your CAE software suppliers to most effectively stretch your limited budget.

Dytran, developed by MSC Software, is a leading software solution for simulating and analyzing the dynamic behavior of structures and systems subjected to transient and vibration loading. Dytran is specifically designed for applications in industries such as aerospace, automotive, defense, and manufacturing.

It offers advanced capabilities for modeling and analyzing complex dynamic phenomena, including structural dynamics, impact, shock response, and acoustic response. The software enables engineers to accurately predict and assess the dynamic performance, durability, and reliability of their designs. With its powerful solver technology and intuitive interface, Dytran empowers engineers to optimize product designs, improve safety, and reduce development time and costs.

These include:

- Accurate, robust analysis for your industry

- Unique combination of simulation technologies

- Dytran for maximizing productivity

- Transient structural analysis (crash/impact)

- Fluid-structure interaction

- High performance computing